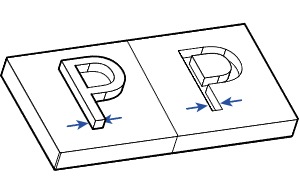

Embossing and engraving

In short

Complexity is free, so use it to your advantage. Adding text or logos to your design is easy and does not take any extra production time. It does enhance the professional appearance of your parts.

Finished your design? Make sure to check:

- Make sure details are no smaller than 0,8 mm.

- Engraved letters are less legible, compensate with larger thickness and depth.

- Use text or numbers to identify your parts and differentiate between versions.

Logos

Details like logos can be embossed or engraved. Make sure your engraved parts are at least 1 mm deep and your embossed parts at least 1 mm high. Small details in the logo should be no smaller than 0,8 mm. This way the details won’t damage and will still be clearly visible after post-processing.

Text

Text that is cut out of the material is much less legible than text that protrudes, as SLS has more difficulty removing material from the former. SLS is, however, able to print text legibly with a thickness of at least 0,8 mm at a height of 1 mm.

Be sure your text is at least 0,8 mm thick and 1 mm high to prevent it from becoming illegible. Make sure to use fonts with mid-sized or wider character widths in a regular font weight or heavier. An example of the smallest legible thickness is 16-point Arial.

Fonts to avoid include any with “condensed” in the name, those with narrow character widths, and anything less than regular font weight.

When engraving text, make sure the letters are no thinner than 0,8 mm. During the cleaning of the parts, the small beads that are used to remove excess powder can get stuck in narrow gaps. Make sure the letters are wide enough to prevent this.

Adding text to your parts can also have a benefit in the production process: it makes them easier to identify. For example, you can add the part name or version number to a non-critical surface.

What’s inside our guidlines?

Our guidelines are filled to the brim with useful information on how to design your models, the newest technologies and specifications for your parts!