Materials

In short

3D-printing is suited for an endless number of applications. The experts – that’s us – can create tailor made solutions to fit your needs exactly. To ensure this best fit, we offer a wide spectrum of materials.

PA 12

Our standard printing material is a Nylon powder (aka PA2200 or PA12), suitable for a wide range of applications. The finish of the products is slightly granular, without a layered distortion. Finished parts can be impregnated with a black pigment. Other colors are available, including a certified food blue.

Depending on the wall thickness this material is very flexible (wall ± 1,5 mm) up to very strong (± 6 mm).

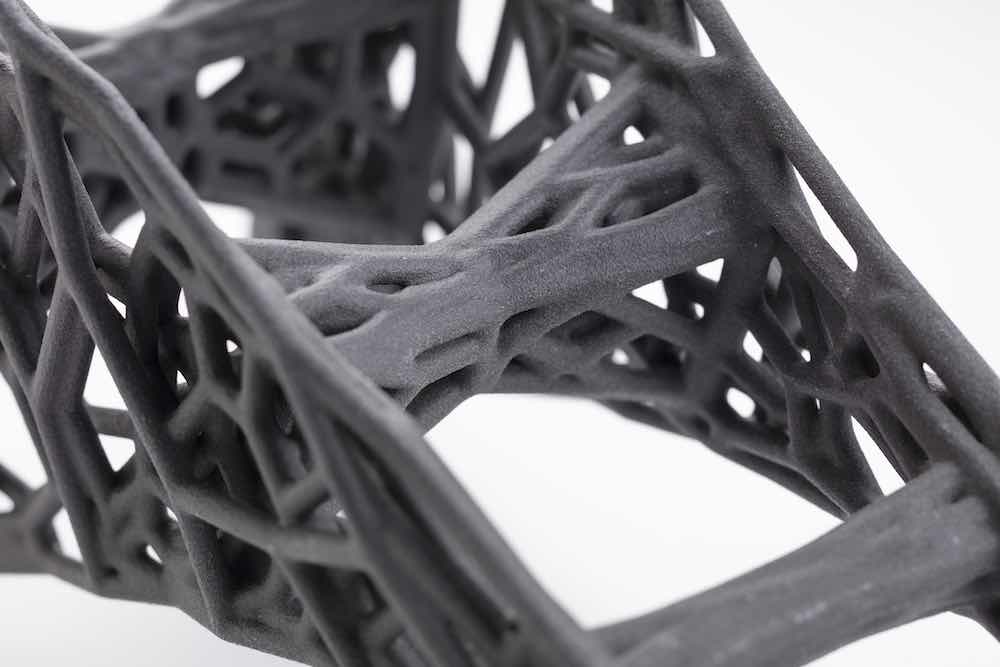

Carbon LW

Stronger still: our Carbon Light Weight (Carbonmide). Reinforced with carbon fibers resulting in a material four times (!) stronger than our regular PA12. A higher tenacity, tougher and higher tensile strength means even more security and durability in heavy duty industrial applications. Temperature and chemical resistant.

TPU

Looking for a material with rubber-like properties? Our TPU 1301 is a thermoplastic polyurethane with very bendable, soft properties. It has excellent physical characteristics and is resistant to wear and chemicals. As a result, it is often used for gaskets, sports soles and footwear, orthopedic models, hoses, seals and wheels.

What’s inside our guidlines?

Our guidelines are filled to the brim with useful information on how to design your models, the newest technologies and specifications for your parts!