Optimization

In short

We have collected a few tips and tricks for you to optimize the design of your parts for the SLS printing process. These tips get you the best result and will reduce printing time and costs of the parts.

Finished your design? Make sure to check:

- Export your parts as a STEP or STL file.

- Specify the desired material, color, and post-processing steps on your technical drawing.

Labels

Adding identifier labels to your parts gives a benefit in the production process: it makes them easier to identify. For example, you could add the part name or version number to a non-critical surface. This will improve identification of the correct part. Not only during the production, but also in use.

If you don’t want the identifier to be on the part itself, you could also consider adding a label on a small pin which can be removed after production.

Stacking

The cost of your part is determined by the material volume and the bounding box of the object. You can reduce costs and printing time by making your parts stackable. Export your parts as separate STEP files and let us know how to stack them in your technical drawing.

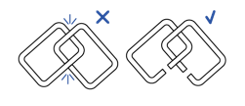

Interlocking

Parts can be printed interlocked. Check the chapter on assemblies to learn more.

However, sometimes interlocking can be undesired. For example, a ring-shaped part, which could accidentally interlock with another part during printing. We always test for interlocking before printing.

File requirements

You have reached the final step in the design process. At Parts on Demand, we accept STEP or STL files. Most CAD software will have the option to export your part in these formats.

If you need any assistance with modeling your parts or if you want us to make small changes, please provide STEP files. These are easier to edit than STLs. Our engineers use Solidworks and Rhinoceros software, so you can also send us your Solidworks or Rhino file.

STL files represent objects by dividing the surfaces into multiple small triangles. The conversion to STL often leads to small errors, like missing faces or gaps. We will always check your files on errors and make sure to fix them before printing.

Please include a technical drawing for each part specifying the material, color, and post-processing services your part requires.

What’s inside our guidlines?

Our guidelines are filled to the brim with useful information on how to design your models, the newest technologies and specifications for your parts!