Rounded edges

In short

3D-printing comes with a lot of design freedom. You can add angles and curves without making the production process more costly or complex. We encourage you to add as many fillets as possible.

Finished your design? Make sure to check:

- Does your part have curves and angles in every direction? Request shotpeening to make sure the surfaces are smooth.

- Add fillets to edges and corners to increase the strength of the part.

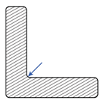

Fillets

Adding generous fillets to connections is crucial to increase structural support. It is important to make fillets as large as possible to increase the amount of surface area involved in a connection. Another way to achieve this is drafting extrusions outwards.

Sharp corners and edges often get softened during post-processing, so adding fillets can also make your parts more predictable and accurate.

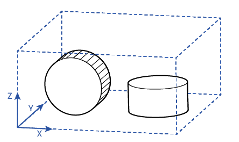

Curved surfaces

Complexity is free, that includes organic shapes and curved surfaces. However, there are a few considerations when creating these shapes.

The print direction is critical to the quality of your parts curves. Curves in the XY-plane will be the most accurate. In the Z-direction, the accuracy is linked to the layer height of the build. SLS printing is a very precise method of 3D-printing. However, on parts that have an angled or curved surface in the Z planes, you will still be able to see some layering. Shotpeening will get you a smooth finish on these surfaces. If a specific dimension or curve it critical to your part, please indicate this on the technical drawing so we can take it into account when setting the print orientation.

What’s inside our guidlines?

Our guidelines are filled to the brim with useful information on how to design your models, the newest technologies and specifications for your parts!