Integrated and flexible:

super smart.

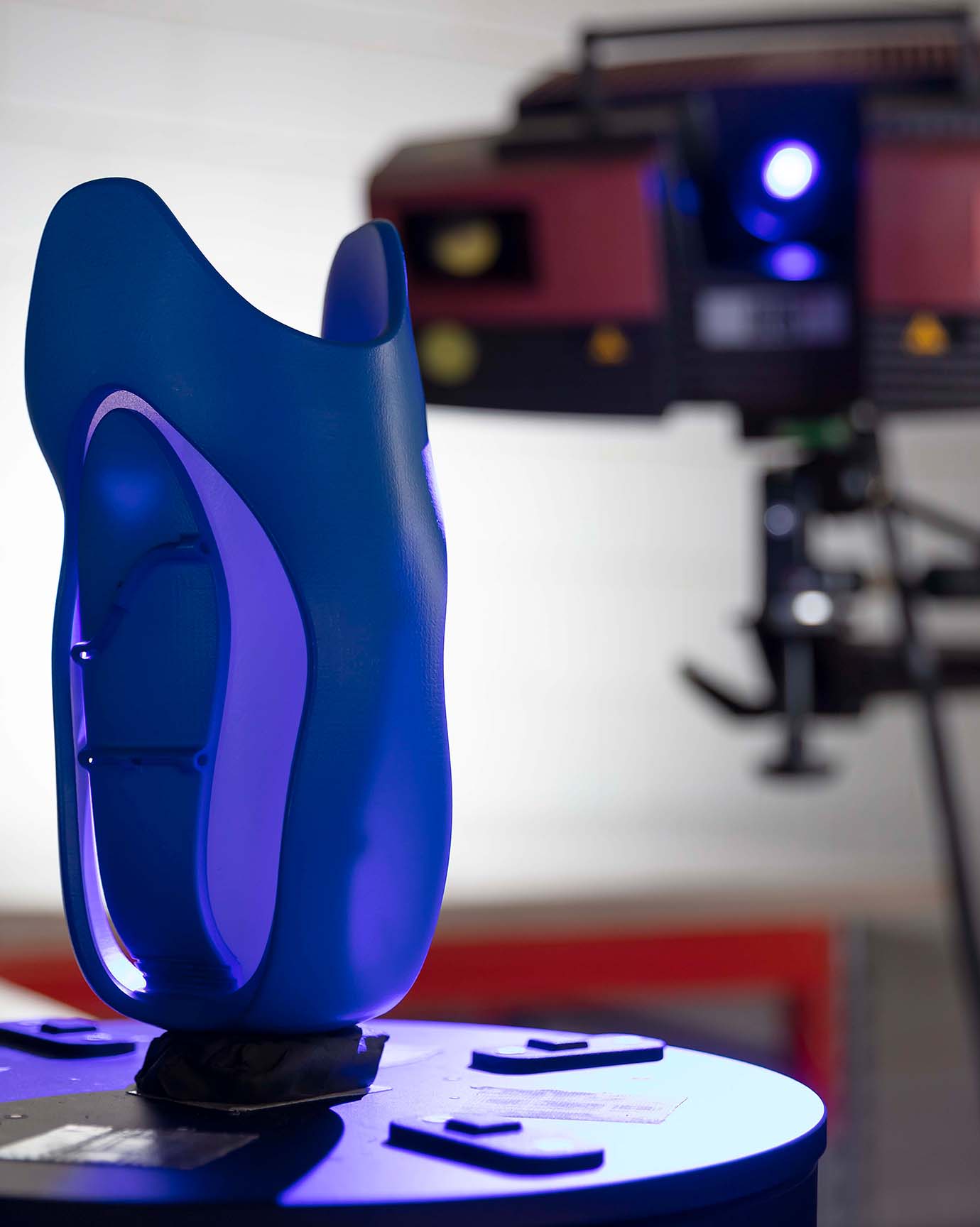

Our integrated production methods in 3D printing allow us to integrate different techniques. And with an enormous flexibility at that! Suddenly, things that seemed science fiction are now possible. That’s what we love. In real life, that is.

Even that is possible with 3D printing.

As well as in other areas, we continue to surprise customers in the field of end-of-arm tooling with clever constructions. Examples? We produce and develop grippers and vacuum tools that work lighter, faster and better. We ensure that pick-and-place robots handle more products per hour. Not only because it’s possible, but also because it makes us happy.

Who needs another reason?

Ready for the next step?

Step out of your comfort zone, go crazy and increase the capacity of your production line by re-engineering the bottlenecks with 3D printed parts. The future is suddenly a lot closer. Or maybe it’s already here.

Do you have any burning questions?

It may be true that 3D printing hasn’t been used as long for production as turning, milling or injection molding. As an engineer, maybe you don’t really have that ‘feel’ with printed parts yet. And you are not confident about how 3D printed products hold up in your machines. We fully understand that! And we will help ease your mind.

So: do you have a 3D printed application in mind? Use a 3D printed part and taste the pudding? See if it will hold up? Then contact Neil for a free sample. On the house!