In times of sunshine

You’ve probably been regularly rubbing yourself with a factored sunscreen for the past few weeks. Wise, because you want to protect your skin from the uv rays in sunlight. To not look as red as a lobster.

Your plastic parts also tend to discolor when exposed to uv light. Now you are already lucky that at Parts On Demand your parts are manufactured with the SLS process. This gives just a bit more options than if they were made through SLA.

Well, that discoloration. Actually, the discoloration of plastic is nothing but an oxidation, just like rust in metals. White plastic becomes a creamy yellow over time. You probably recognize this process from plastic garden furniture.

The same thing happens with 3D printed parts. If they are exposed to sunlight for a long time, white parts will turn yellow, black parts will get a kind of brown sheen.

The cause of this oxidation is not moisture – as with metals – but UV light. To do something about that, we have a few options for you.

The first option: a coating that allows you to put on your part as if it were a T-shirt.

The second option: a UV-resistant additive with which we impregnate your part. So basically your sunscreen, but with a slightly longer shelf life.

Option One

The former solution is a coating. Just as you can protect metals with a coat of paint, you can do the same with plastics. This seals the surface completely with an industrial lacquer. Your part looks slick and is protected from UV radiation

But for technical parts, a coating is not always the ideal solution. A coating can damage and, another thing: it means an extra layer, which you have to take into account in your dimensions and tolerances. On to our option two.

Option Two

Just as we can impregnate parts with a color at Parts On Demand, we can also impregnate them with a uv stabilizer. Or even a combination of both.

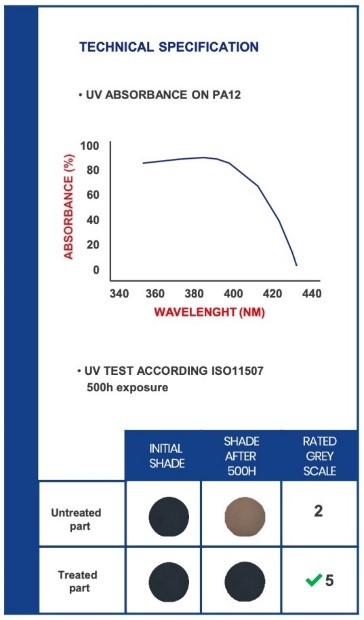

Under the influence of pressure and heat, the UV stabilizer, as well as the dye, penetrate the surface of the part. The molecules of the stabilizer react when exposed to UV light and protect the color and the plastic itself.

We can make the result visible in a so-called ISO11507 exposure test. With this we measure the “lightfastness” of the color, at the beginning of the test and after 500 hours of UV exposure. Color deviation is rated on a scale of 1 to 5, where 5 means there is no deviation and 1 means the color is completely faded.

We conducted this test on black parts. An untreated part scored a 2 on that scale of 5 after 500 hours of exposure to a UV light source. The same part but treated with the uv stabilizer scored a 5 after the same 500 hours of exposure! This means that it has retained its original color without fading.

Cool right?

But unlike our Parts, most people are quite willing to discolor when we are exposed to the sun. But the right color – and that’s why we smear.